Structural inspection of digesters tanks

The inspection of the covered zones of the digester tanks used in a plant for sewage treatment was carried out as a predictive–preventive maintenance activity, and also, aiming to follow the manufacturer recommendations as well as the related normative used in its construction. The results obtained were analyzed according to API 650 and API 653 codes.

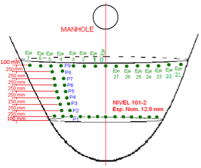

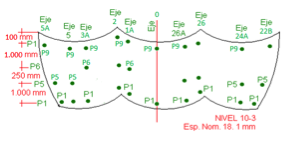

The anaerobic digesters are part of the sanitation process of the sewage which have the aim to clean the Medellín river. During this process large quantity of sludge is accumulated in different zones of the digesters causing wear due to corrosion in their structure. In this project it was defined the methodology to analyze the integrity of these kind of tanks which involved the location of the regions for inspect, as well as the definition of the visual and ultrasonic inspection process in order to evaluate the welds integrity and measure the plates thickness, aiming to estimate the approximate wear rate caused by corrosion and the digester lifetime.

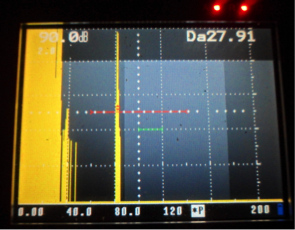

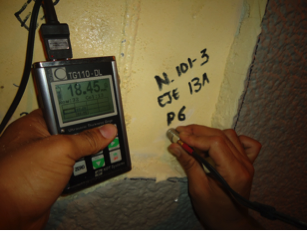

The inspected places were selected in order to guarantee the traceability for future inspections. On the other hand, the methodology and inspection procedure were made according to the SNT-TC-1A practices. In each tank around 1000 measurements of thickness were made and 86,2 meters of welds were analyzed.

The visual inspection showed the presence of some spatter, marks of the lifting and misalignment between plates. The ultrasonic testing indicated the presence of some spherical pores, group of pores and some slag inclusions. Regarding the plates thickness measuring, it was not observed critical regions with significant variations, which are usually related to corrosion.

The analysis of the results according to API 653 standard allowed to define the timespan for the next inspection, in the same way the approximate corrosion rate was estimated and the lifetime of both tanks.