Surfaces Engineering

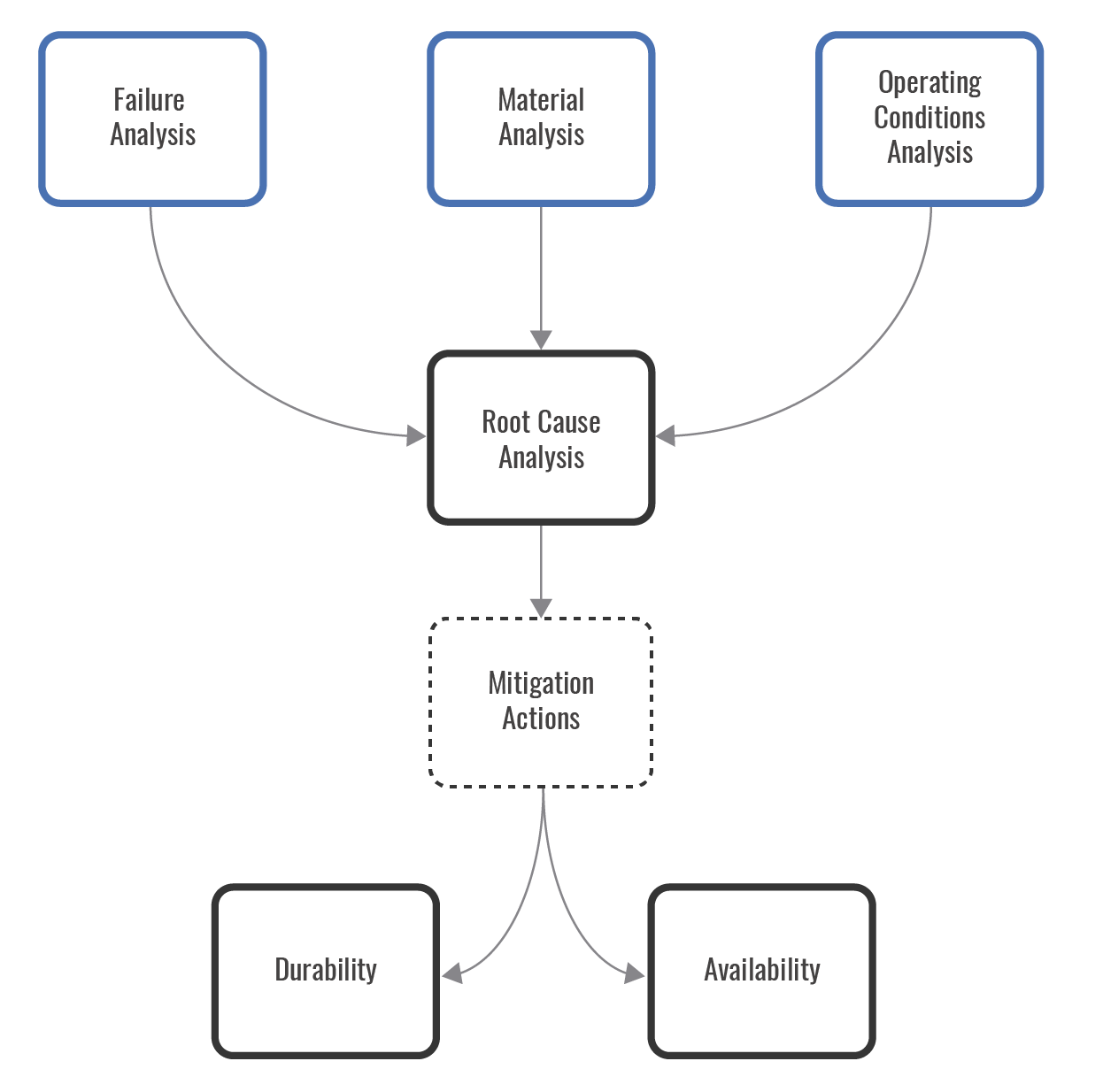

1. Root cause analysis

Root cause of failure, excessive wear and non-scheduled stops of the critical components and equipment are identified to propose recommendations and implement solutions in order to increase the lifetime and efficiency of systems.

Root cause analysis follows the Kobaltum method:

- Immersion

- Analysis

- Solution

Immersion

The operating conditions of the productive system are analyzed with emphasis on the failed component. The following information is analyzed:

- Design requirements

- Detailed drawings and assembly of the equipment and its surrounding components

- Operating and environmental conditions

- Destructive and Nondestructive testing records

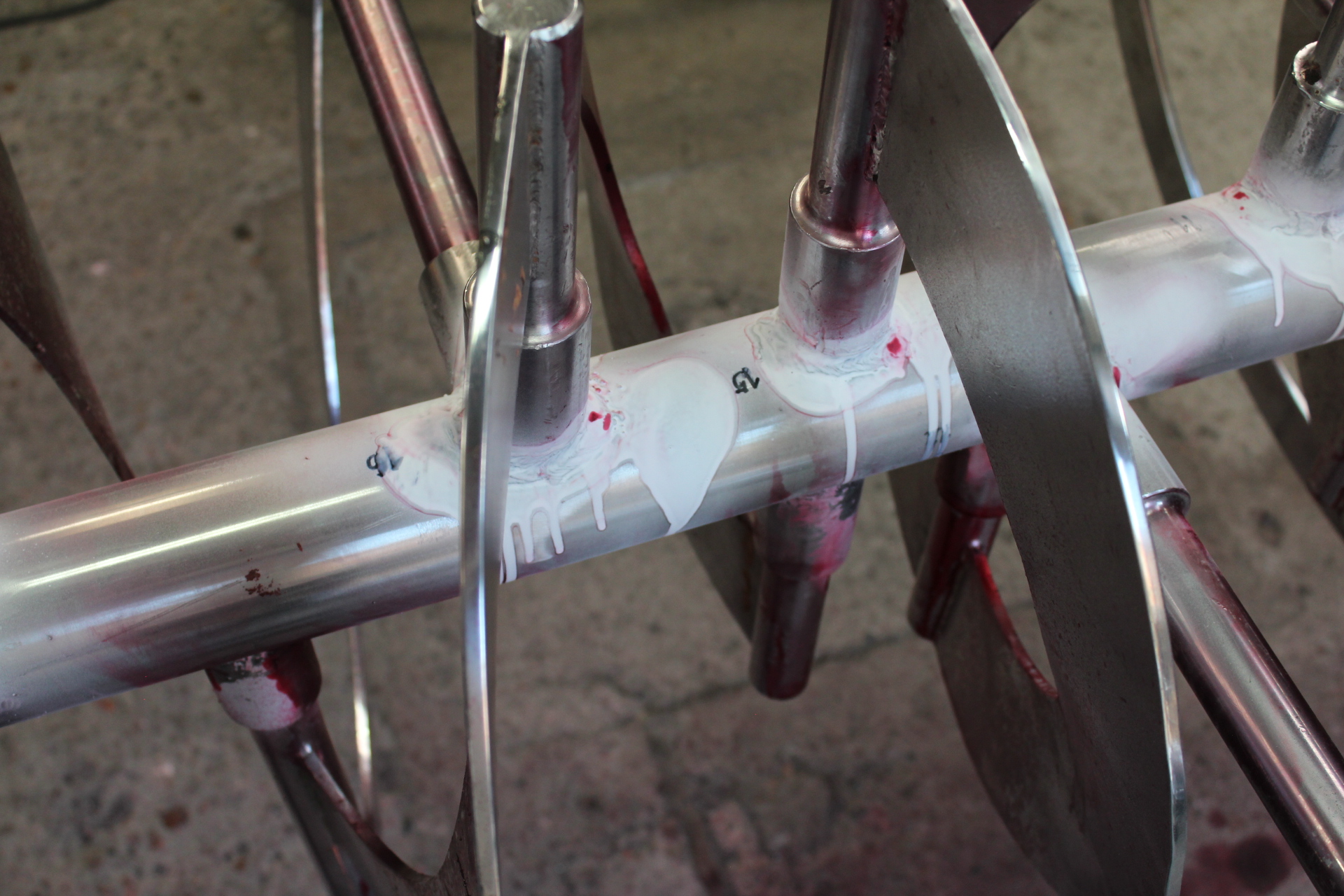

Liquid penetrant inspection of welding joints in a mixer machine, which presents numerous discontinuities between its principal shaft and the pivots of their blades. Failure occurred during operation.

Analysis

The information obtained during the Immersion is analyzed together with the inspection of the failed surface, the material characterization and the operating conditions analysis. Fractography analysis is performed in-situ and in laboratory using microscopy techniques, which allow identifying the main surface characteristics and wear mechanisms in the failed component.

Fractography analysis is performed in-situ and in the laboratory, this last one using microscopy techniques which allows to identify the main surface characteristics and wear mechanisms presented in the failed component.

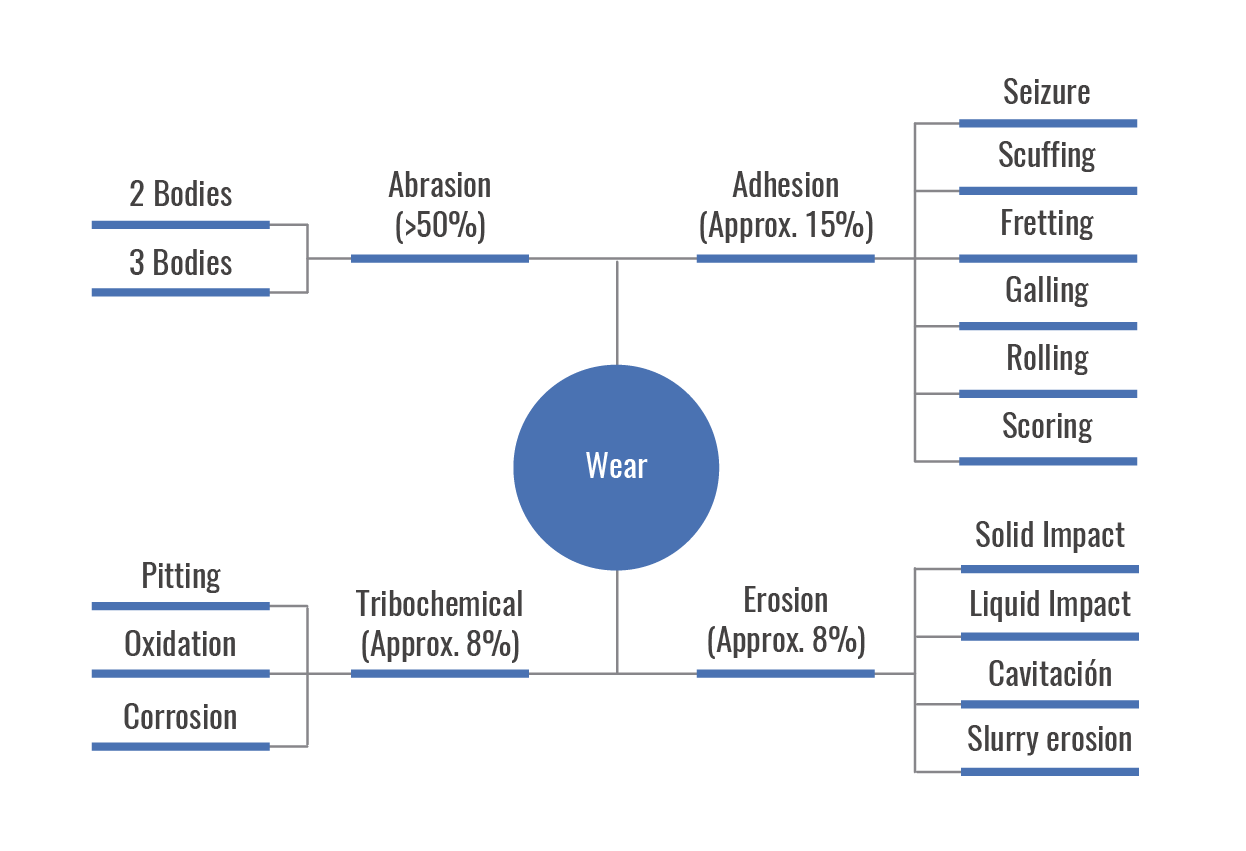

Different wear mechanisms and common failures in industry

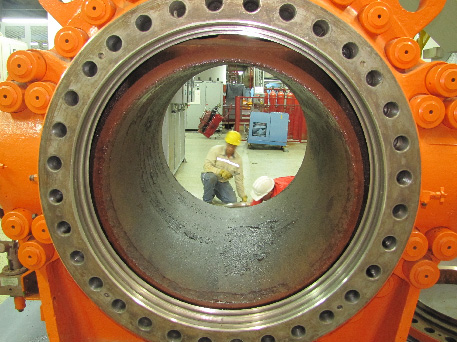

Suction pump impeller which presented catastrophic failure at 2% of its lifetime. Excessive wear due to slurry erosion.

Profile of suction pump impeller which presented catastrophic failure at 2% of its lifetime. Excessive wear due to slurry erosion.

Chemical, physical, mechanical and microstructural properties characterization is performed to compare the results with the information provided in the data sheets and / or record purchase of the costumer. Thereby, a conclusion can be reached about the incidence of the material properties regarding the cause of failure

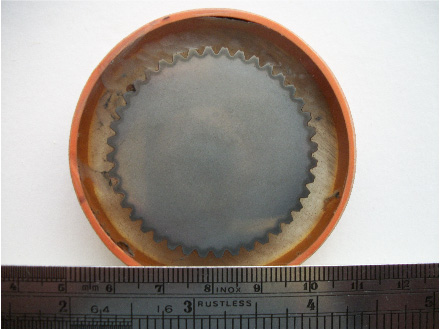

Macroetching of the cross section of a pump power transmission shaft. Macroetching helps determine the execution of heat treatments or thermochemical treatments, which are both used to improve the mechanical properties of components to make them suitable for the application.

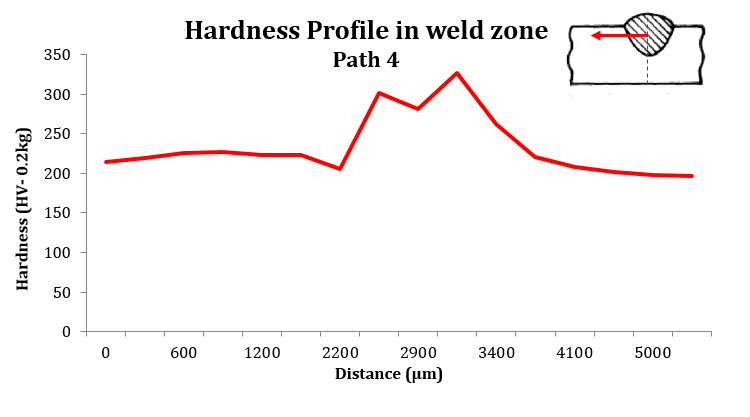

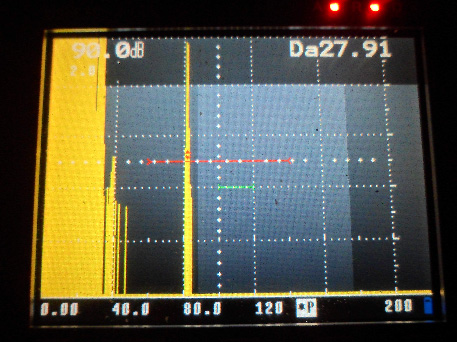

Microhardness measurements near the welding between the lower head and the shell of a tank for gas storage. The measurements were carried out to characterize the mechanical properties of the weld, the heat affected zone and the base metal.

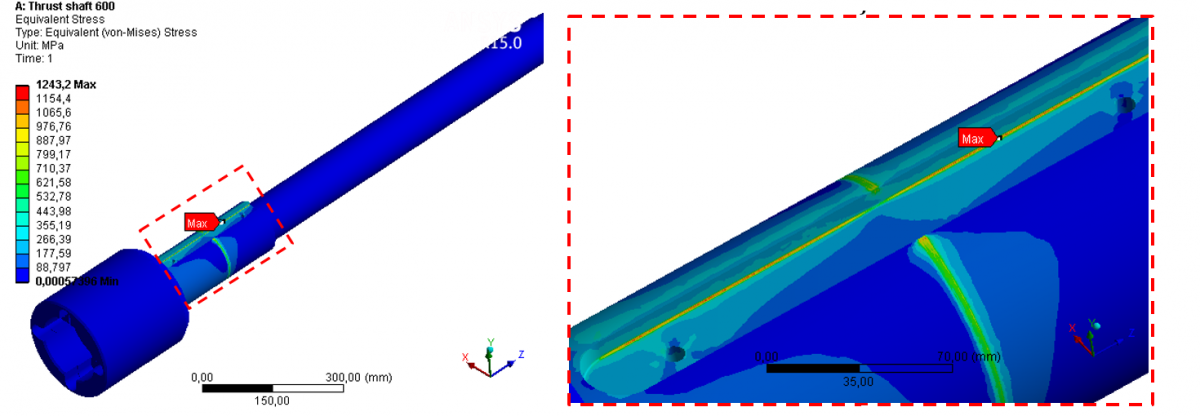

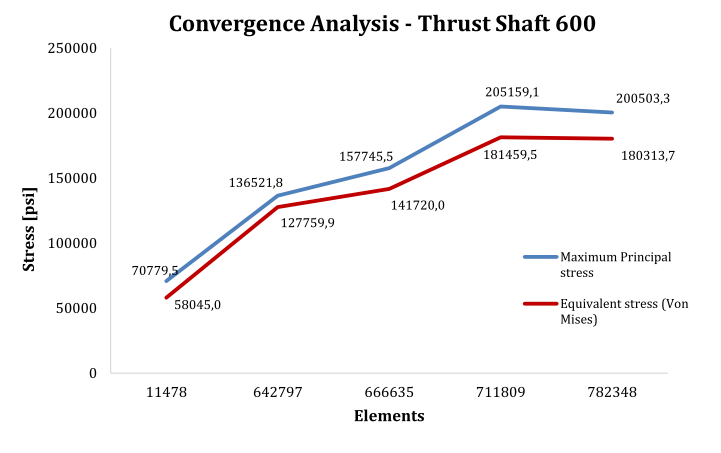

Finally, the operating conditions are evaluated through analytical and numerical models. The analyses are made in order to identify the stress state of the component(s), the safety factor(s) and the estimated lifetime, and to compare them with the conditions during normal or critical operation or throughout any unusual event that might cause a failure or a non-scheduled stop.

Stress analysis, safety factors and estimated lifetime calculated for a polymer extruder shaft.

Convergence analysis for numerical simulation of a polymer extruder shaft.

Solution

The implementation of the Kobaltum method allows identifying the root cause of failure, wear or inadequate operation of critical components or systems. With the unique standpoint offered by the failure analysis, material and operating conditions, it is possible to implement solutions that help increase the durability and efficiency of a productive system.

2. Integrity Analysis

The integrity analysis is performed in a surface, component or system in order to determine its integrity as well as to estimate its lifetime so that preventive and predictive maintenance tasks can be planned. This significantly reduces affectation of the system due to non-scheduled stops or catastrophic failures.

Through destructive and non-destructive testing, the structural integrity of components and mechanical systems is evaluated. Kobaltum has a Level II inspector on ultrasonic testing and a CWI Inspector for this purpose. Following aspects are covered in the integrity analysis:

- Estimation of wear rates and lifetime of components

- Programming of preventive and predictive maintenance based on reliability of mechanical equipment and structures

- Quality assurance of raw materials or finished products

Inspection through ultrasonic testing of the sanity of welds and plates thickness of a biodigester tank.

Identification of discontinuities in a steel pipe using ultrasonic testing and liquid penetrant inspection.

3. Welding and recovering

Welding and recovering services are focused on those components that are made only upon request due to their complex shape or low availability. The intervention of those parts is carried out aiming to increase its lifetime as well as ensure its availability for the operation. The recovering is made through welding application and allows the components to return to a condition similar to their initial state.

A feasibility study is made in order to assure that a component can properly operate after recovering. Subsequently, a Welding Procedure Specification (WPS) is developed where the necessary parameters for welding, material specifications and operating conditions of the component are considered. Finally, the welding procedure and the welder operators are qualified in order to validate that the design fulfills the standards and customer requirements.

Kobaltum has a CWI inspector approved by the American Welding Society to develop the welding and recovering activities.