Failure in a drilling motor used for crude extraction

A motor used in the drilling process for crude extraction presented failure causing a non-scheduled stop in the productive system of the company and losses of profit.

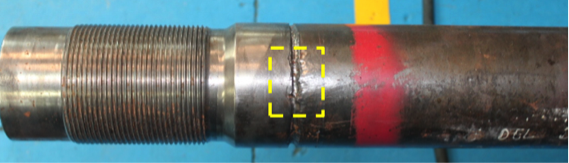

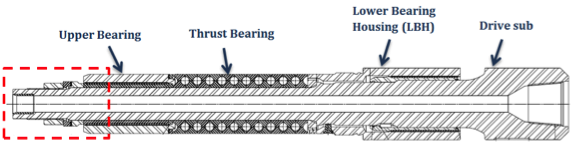

Once the maintenance team inspected the motor they found several components affected, among which stood out the thrust bearing and the upper bearing, therefore it was necessary replace the whole equipment in order to restart the operation.

The failure surface of each component that showed some affectation was analyzed aiming to identify the principal wear mechanism and determine the root cause of failure.

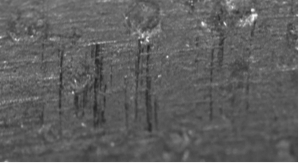

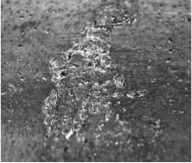

In general the wear mechanism found in most of the components was erosion caused by liquids with solid particles (slurry erosion), nevertheless, in the inner ring of the thrust bearing it was found an indication of abrasion along it, as well as marks in the contact area of the balls, these last ones caused for an excessive axial load over the component.

Another inner ring of the thrust bearing showed a crack that advanced in both longitudinal and circumferential directions, which is associated equally to excessive axial loads and impacts. The previous indications allowed to suspect that there was a clearance in the system, which finally generated the failure.

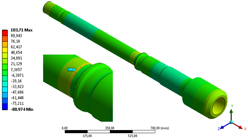

Additionally, an analysis of the operating conditions of the motor shaft was carried out. ANSYS® software was used in order to perform a finite element analysis of the operating conditions and it was complemented with an analytical model of the stress state of the shaft as well as the calculations of the static and fatigue safety factors. The results shown that the design of the component was strong enough to withstand the operating conditions, offering “infinite life” for the application.

Finally, the materials characterization was carried out for the failed components through the chemical composition, the microstructure and the hardness analysis, and it was found that the material of the upper bearing was not resistant to erosion wear.

It was concluded that the failure started as erosion in the upper bearing, which caused a clearance in axial direction that allowed the inlet of the slurry to the system and generated the wear in the other components. The clearance in the upper bearing caused a misadjust in the inner rings of the thrust bearing carrying as consequence the presence of impacts and angular misalignments; those components were fractured due to the atypical conditions and the excessive axial loads generated.

It is recommended to use materials with high hardness in order to avoid wear problems in components that are submitted to environments with presence of abrasive particles and slurry, which is reached through heat treatments, thermochemical treatments or applying hardfacing in their surfaces. Similarly, it is recommended to validate the materials selection through wear tests, which is at the same time a tool for programming the predictive-preventive maintenance activities through the knowledge of the wear rates of the components.